青岛久隆医疗专用吸塑热合封口机是综合国内外吸塑封口机及济南高周波机的性能,以提高生产速度及其降低产品的不合格率,避免因吸塑封口加热易变形,也避免济南高周波包装时产生磁场等弊端。久隆新型 环保医疗医用济南热合机已获得ISO9001质量体系认证和CE认证。适合于医疗产品对环境的高要求;专业针对生产医疗包装特卫强透析纸+泡壳专用设备,设备内部均采用进口、质量稳定的配件,采用欧姆龙温控系统,密封式加热设计,模具温度更均衡,±1℃的误差。设备稳定性较高,故障频率低,产品外观精美,适用于医疗PETG、PET、APET、PVC、PS泡壳等塑胶吸塑盒与医疗用复合纸、透气纸(Tyvek-10732B)与杜邦(特卫强)透析纸的焊接,适合一类、二类、三类医疗器械净化车间的生产,设备制造标准为1万级、十万级等,系列设备封口质量已达到生物相容性(Biocompatibility)封口检测标准、并经过真空泄漏、封口剥离、颜料渗漏、膨胀及加快老化等试验,是医疗制品包装,食品企业、药品企业、质检机构、包装生产企业的专用设备。同时我们可较快速度为客户制作模具及新品的技术开发,可为客户提供2、3类医疗器械及生物制药外包装吸塑壳的专业厂家以及杜邦特卫强透气纸的供应商,是您购买久隆医用封口机的理想选择。

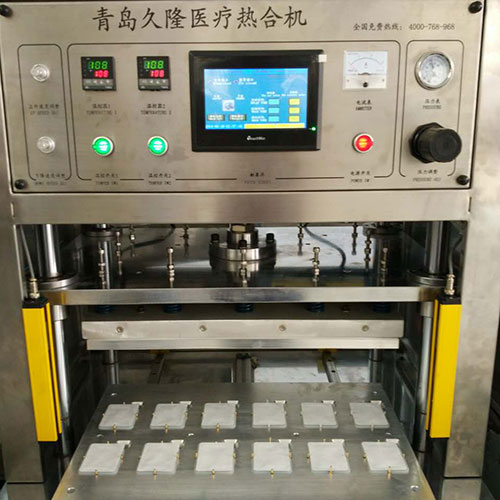

久隆机器配置参数

1、上压板尺寸:400*600mm

2、下压板尺寸:600*800mm

3、上模行程:150mm

4、工作位采用自动推盘,并采用直线导轨限位;

5、气动元件:台湾“亚德客”

6、人机界面一体控制:时间制控制和PLC触摸屏智能控制

7、继电器:日本“OMRON”

8、电热管:采用PID控温技术

9、机架采用:铝合金支架+不锈钢板+不锈钢方管

10、机器所有零配件:全部电镀处理或铝合金

11、机器尺寸:880*780*1680mm

12、上压板采用加大四柱导柱,高强度滑动滑轮。

13、上下压板均经过精密加工,表面平整光滑。

14、模具均为铝合金制作,热合面经过高温处理,防沾,防腐。

15.电源AC220V或AC380V ,30A

久隆机器技术特征与其它机不同的功能

技术特征:

微电脑控制,大液晶显示

压力调节采用原装进口传感系统

数字P.I.D.温度控制,设备全自动化测试

下置式气缸同步回路,保障压力均衡

设备机箱机架一体封闭式,保障了热封面加热的均匀性

设备热封面独立双控控温,加长的热封面可满足大面积或多试样同时封口,并支持多种热封面形式的定制

手动与自动开关双重模式,人性化结构设计

防烫设计和漏电保护设计,操作更安全。

1、推盘采用电机或气动自动推拉,减轻劳动力。

2、设备机箱一体式304不锈钢结构,内有防尘装置,设备内部采用进口航空美铝和不锈钢材。

3、该机器有专用滑块的固定模具装置,方便快捷更换不同产品模具。

4、所有排气汇集到一根气管通向室外排送,防止污染空气;

5、上模热合压板加大,并且带制锁装置;

6、PLC+触摸屏控制程序非常精细,并且人性化设计动作都有自动与手动之区别,更能适合高难度产品的生产和调节。

服务热线service

服务热线service