手持式济南超声波焊接机

操作说明

1.过载指示灯:机器正常工作时过载指示灯为熄灭状态。当本机济南超声波振动异常时,此灯会亮,并停止发振。如果操作过程中过载灯亮,原因可能有: (1)焊头松动; (2)调波不当; (3)焊头破裂。应对摸施有: (1)锁紧焊头; (2)重新调整声波; (3)换修焊头.

2.振幅表:空载时,表示焊头谐振的程度。指针越低越好,视焊头与输出段数而异,通常在5%~15%之间,负载时,表示输出功率的大小。

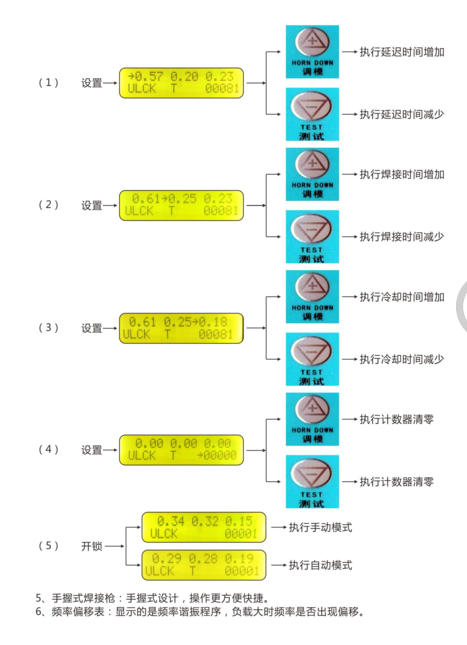

3. LCD显示屏:LCD显示有延时时间、焊接时间、冷却时间等。通过它可以很精确的控制机器工作周期。功能按键:设置按键、调模按键、检测按键、开锁按键、启动按键、停止按键。

服务热线service

服务热线service